Brewery Spent Grain Dryer

Daily Capacity : 300-4500kg/h

Final Moisture : 10±5% Adjustable

Material : brewery spent grain, vinasse, distillers' grains, etc

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 300-4500kg/h

Final Moisture : 10±5% Adjustable

Material : brewery spent grain, vinasse, distillers' grains, etc

Brewer's spent grain (BSG) or vinasse is the by product from brewery process. It contents a large amounts of nutrients. After being processed, the dried vinasse/distiller's grains are good materials for animal feed.

Our spent grain drying system is as followed: If the moisture of the wet spent grain is higher than 75%-80%, which needs the screw dehydrator to reduce the moisture to 62-65%, to reduce the burder of the dryer, then goes into the drying process, the final moisture of the spent grain can reach 12-15%;

Besides, We can offer the packing machine after the drying and crushing. We have the packing machine for 25kg/bag,50kg/bag, which can adjust according to customers' needs. We can also offer the full pellet plant, by adding some auxiliary materials, makes it into high-quality animal feed pellet.

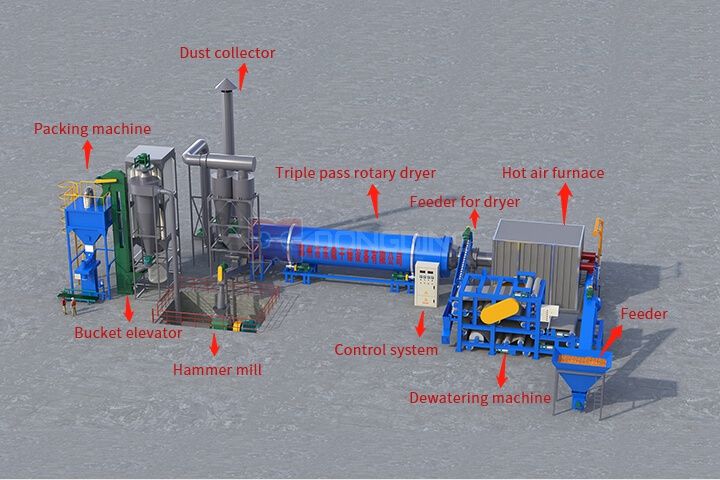

Brewer's spent grains dryer mainly consists of heat source, feeding machines, feeder, rotary drum, discharging machine, draft fan, discharge and power distribution cabinet.

The brewery spent grain drying plant process as following: wet BSG-stirring to uniform--preliminary dehydration--drying--crushing--packing; then the final product sold into the market.

Brief Drying Process

1.Feeding: Wet spent grains is fed into the dryer.

2.Lifting and Dispersion: Lifting plates on the inner wall of the drum continuously lift and disperse the spent grain, forming a dispersed "material curtain" that significantly increases raw material’s surface, letting the wet spent grain contact with the hot air fully later.

3.Hot air contacts with the spent grain: High-temperature hot air (usually introduced from the feed end or discharge end) penetrates the falling material curtain and contact with the wet spent grain directly.

4.Heat and mass transfer: The hot air transfers heat to the spent grain, and the water in the wet spent grain evaporates quickly.

5.Discharge and Dust Removal: The dried spent grain is discharged and collected from the discharge port. The wet exhaust gas is purified by a dust removal system (such as a cyclone + bag dust collector) before being discharged.

a. Compared with the single rotary dryer, the floor space of the spent grain dryer is reduced by about 50%, and the investment reduced by about 40%.

The thermal efficiency of the dryer is as high as 70% (the thermal efficiency of the traditional single rotary dryer is only 35%)

b. A special breaking and lifting device was installed inner the dryer, which can effectively prevent the material from sticking to the wall and scorching;

c. The dust removal device can completely avoid the dust pollution in the drying process and meet requirements of environmental protection;

d. The material flow speed was controlled by frequency conversion; and the final moisture can be easily controlled to meet the needs of users;

e. It is equipped with a new type of energy-saving hot blast stove, which is highly efficient and energy-saving, thermal controllable, and reduces the operating cost.

f. Multiple heating source can be used, such as coal, gas, oil, biomass particles, steam, etc.

| Device Specification | DDJG1210 | DDJG1410 | DDJG1610 | DDJG2010/3 | DDJG2210/3 | DDJG2510/3 | DDJG2512/3 | DDJG2912/3 |

| Daily Processing Capacity(t/d) | 33.6 | 40.8 | 58.9 | 131.4 | 145.0 | 167.7 | 204.0 | 247.0 |

| Daily Output(t/d) | 15.6 | 19.2 | 27.7 | 61.8 | 68.2 | 78.9 | 96.0 | 116.2 |

| Water Evaporation Capacity (t/h) | 0.75 | 0.90 | 1.30 | 2.90 | 3.20 | 3.70 | 4.50 | 5.45 |

| Raw Material Water Content(%) | 60-80 | |||||||

| Dried Material Water Content(%) | 12-15(adjustable) | |||||||

| Drying Temperature(℃) | 350-550 | |||||||

| Total Weight(kg) | 32 | 40 | 55 | 95 | 100 | 125 | 145 | 165 |

| Plant Area(㎡) | 15000 | 17000 | 21500 | 26500 | 28500 | 370000 | 41000 | 45500 |

| Device Specification(m) | 5*14 | 5*14 | 6*16 | 8*16 | 8*16 | 10*16 | 10*18 | 10*20 |

Brewery Spent Grain Dryer

Alfalfa Rotary Dryer

Yeast Dryer

Pomace Dryer

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com