Practical significance of sludge drying

Time : 2019-01-04 Writer : ddjx

Efficient municipal waste water treatment produces vast amounts of sludge. Sludge management is an integral part of any modern municipal waste water treatment plant: it is important not to lose the nutrients in the sludge, to make use of its material and energy, and to dispose of it efficiently and sustainably.

The practical and technical challenges of sludge handling are:

stabilising – sludge is not inert and can have an unpleasant odour;

reducing the water content and sludge volume to the minimum;

utilising the energy potential when economically possible;

reducing the amount of harmful micro-organisms if people, animals or plants are in contact with the sludge; and

recovering phosphorus for agriculture.

Sludge drying

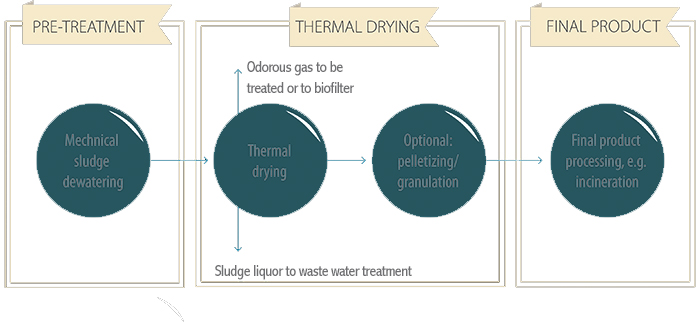

Thermal drying is a technology that aims to significantly reduce the water content of sludge. Drying is mostly used in large waste water treatment plants to increase the heat value of sewage sludge for incineration. Also, drying for agricultural disposal is possible, but not often practised because of its high costs. The removal of water by evaporation from the treated and dewatered sludge increases the dry solids content of the sludge, and reduces both sludge volume and weight. Sludge drying is applied for dewatered (20–30 % DS) primary and/or excess sludges as well as digested sludge after dewatering. Due to the high investment costs, it is usually restricted to large plants. After drying, the solids content is between 50 and 90 %.

Thermal drying is based on the use of heat to evaporate water from the sludge after dewatering. The energy input in dewatering is much lower than in drying, thus a high DS content after dewatering is required. Thermal drying processes are divided into two main categories – direct (convection drying) and indirect (contact drying) heating. This classification is based on how the thermal energy is applied to the sludge in order to increase the temperature.

Direct drying

In direct drying of sludge, heat convection is achieved with direct contact with hot air or hot gases. The sludge’s temperature is increased and water is evaporated. Typical direct drying equipment is a rotary drum dryer or belt dryer. Temperatures of about 450–460 °C (drum) or 120–160 °C (belt) are applied for about 5–10 minutes (drum) or 40–60 minutes (belt dryer).

Indirect drying

In indirect drying, a solid wall separates the sludge from the heat transfer medium, usually hot water, oil or steam. Typical, indirect drying equipment include vertical tray dryers and horizontal disc, paddle or spiral dryers as well as fluidised bed dryers. Temperatures of about 160–200 °C for steam as the heating medium and 190–240 °C for thermal oil are applied with disc dryer for 45–60 minutes, for example. The product temperature is 85–95 °C during the drying stage and exhaust air temperature is 95–110 °C.

Dongding sludge rotary dryer is a typical direct dryer, which has the following advantages:

1. The hot flue gas directly contacts with the materials, sufficient heat exchange and high production capacity.

2, Reasonable system configuration, it can use part of coal powder drying for fuel production, reduce costs and secondary pollution.

3, The system is equipped with PLC control system and video monitoring system, with a high degree of automation and simple operation;

4, The system through a unique sealing structure, no leakage, completely solve the sealing difficulties, to achieve a full range of non-oxidation negative pressure operation, eliminate the possibility of lignite combustion explosion, safe and reliable operation;

5, Low investment, low operating cost and and short investment recovery time.

Dongding has led the way in custom cylinder dryer design and manufacturing since 2005. To learn more about our product, contact us today!

Hot Products

Wood Chips Dryer

Sawdust Rotary Drum Dryer

Biomass Dryer

Biomass Pellet Production Line

Biomass Drying Machine

Bagasse Dryer