Coal slime drying technology

Time : 2019-01-09 Writer : ddjx

Characteristics of coal slime

Coal slime has high water content, large viscosity, small particles, not easy to transport, its economic value is low, very unstable, easy to weathering, not only waste energy, pollute the environment, but also seriously affect the health of coal mine workers and local residents, even restrict the normal production of coal mining enterprises.

Dongding coal slime rotary dryer

According to the characteristics of different coal slime, Dongding has developed a special coal slime dryer, strictly control the drying temperature of the dryer, pressure, air volume, speed, and equipped with different forms of feeding device, cleaning device, crushing device, fully realizing heat exchange and thermal transformation, the drying efficiency and heat utilization rate are improved, the emission of exhaust dust are reduced, achieving energy saving and environmental protection.

Application:

The system is mainly suitable for materials with high water content, fine granularity and large viscosity (coal slime, flotation tail coal, mixed coal, pressurized tail coal, concentrate powder), and can also be used in building materials, mines, clay, sand, limestone and chemical industry, metallurgy, electric power and other industries.

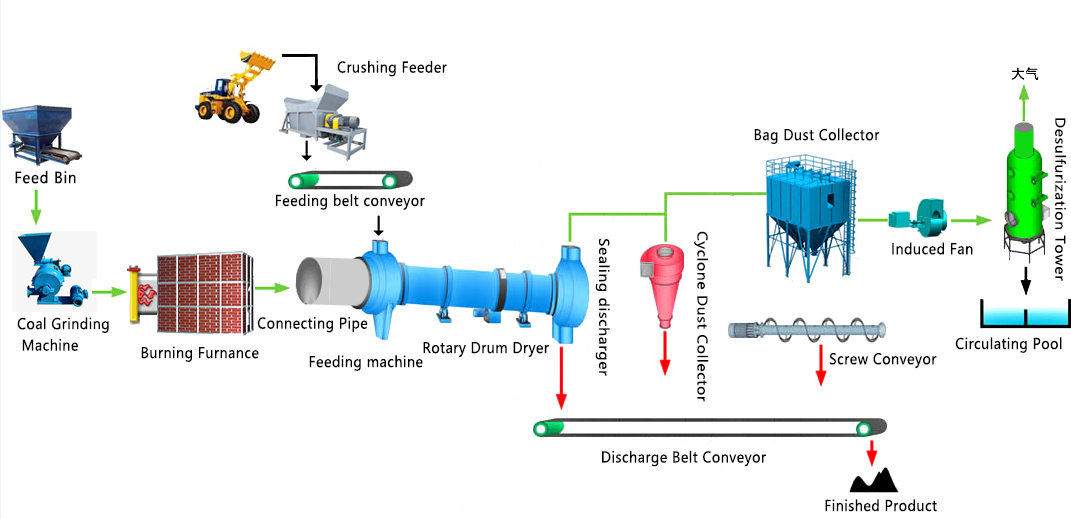

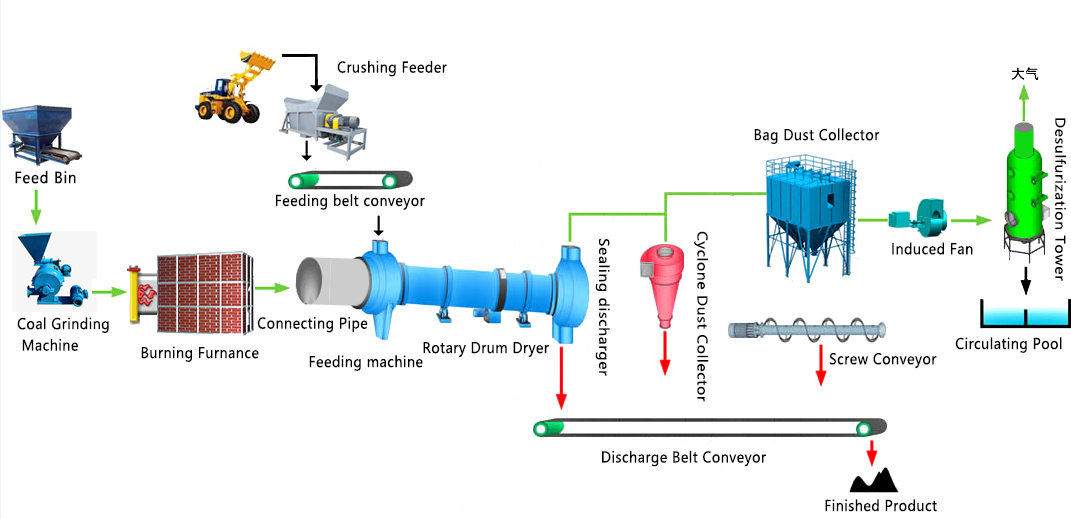

Dongding coal slime drying system

Advantages of coal slime drying system

1. Large processing capacity, less fuel consumption, low drying costs;

2. Downstream drying mode, hot air and wet materials are from the same side into the dryer, obtaining a high evaporation intensity and high thermal efficiency;

3. According to the properties of different coal slurry to change the operating parameters, so that the material can be evenly transmitted, achieving more adequate heating exchange.

4. New feed and discharge device, eliminating the feeding blockage, discontinuous, uneven and recharge, reduce the load of dust removal system.

5. New internal structure, eliminate the adhesion phenomenon of the inner wall;

6. According to user requirements to control product granularity and moisture, finial products can below 8% , granularity can be controlled below 8mm.

Hot Products

Wood Chips Dryer

Sawdust Rotary Drum Dryer

Biomass Dryer

Biomass Pellet Production Line

Biomass Drying Machine

Bagasse Dryer