Compound Fertilizer Dryer

Time : 2019-03-15 Writer : ddjx

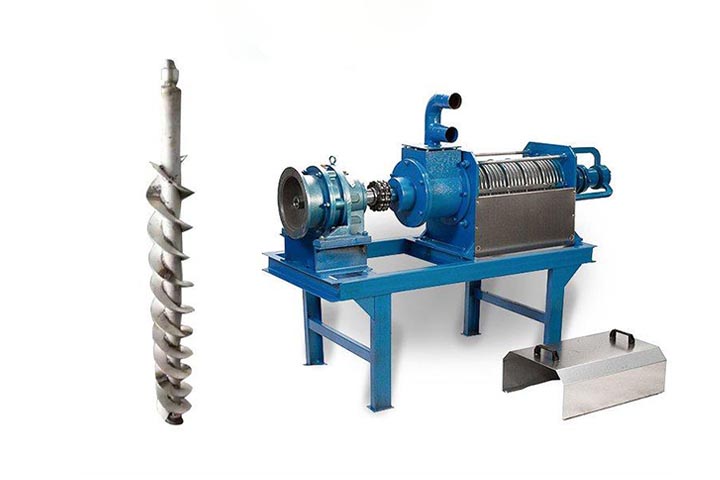

Compound Fertilizer Dryer Introduction

The dryer is designed for compound fertilizer production process and suitable for each system of compound fertilizer production line such as preliminary drying handling NP compound fertilizer.

While using as dryer for granulated fertilizer, flow direction of flue pipe gas and material shall adopt downstream manner; inlet gas temperature of flue pipe gas can be decided according to operation conditions of each system. In general, it shall be less then 400℃. It can achieve stipulated final water content of each density compound fertilizer as national standard.

Table of Technical Parameters for Dryer

| Specification(m) | Productive Capacity(t/h) | Rotating Speed of Shell(r/min) | Inclination of shell (°) | Inlet air temperature(℃) | Motor power(kw) | Speed ration of reducer | Total weight of equipment(kg) |

| Φ3.0×26m | 25~35 | 4.00 | 3.5% | <350 | 110 | 45 | 115 |

| Φ3.0×30m | 25~40 | 3.85 | 3.5% | <350 | 110 | 45 | 130 |

| Φ3.2×30m | 35~50 | 3.85 | 2.0 | <350 | 160 | 35.5 | 155 |

| Φ3.6×32m | 50~90 | 2.2 | 2.0 | <350 | 200 | 35.5 | 175 |

| Φ3.7×31m | 50~90 | 2.2 | 1.26 | <350 | 200 | 71 | 195 |

| Φ4.3×33.5m | 200~250 | 3.4 | 1.83 | <350 | 470 | 45 | 256 |

Note: Productive capacity of dryer has relative to inlet material, original water content, outlet water content and inlet wind temperature and process as well as site conditions. All data in the table is only for inference.

Product Advantages

1.Low investment, high efficiency, good economic returns.

2.Energy saving and consumption reduction, no three wastes discharge, stable operation,

3.Wide application. This system is suitable for compound fertilizer, medicine, chemical industry, feed and other raw materials.

4.Downstream drying. The temperature can keep the compound fertilizer nutrition activity.

5.Multiple heat source choice. Heating supply can be selected according to different fuel type(coal, oil, gas, biomass pellet etc. ).

Hot Products

Wood Chips Dryer

Sawdust Rotary Drum Dryer

Biomass Dryer

Biomass Pellet Production Line

Biomass Drying Machine

Bagasse Dryer