Key points for choosing large Clay Nickel Ore Drying System

Time : 2019-04-12 Writer : ddjxFor the nickel ore dryer design, it needs to overcome many difficulties, to fully consider the characteristics of nickel ore, such as high moisture, high viscosity and so on. In order to achieve the expected process performance, in the design of nickel ore dryer production line in the process, we need to pay attention to the following matters:

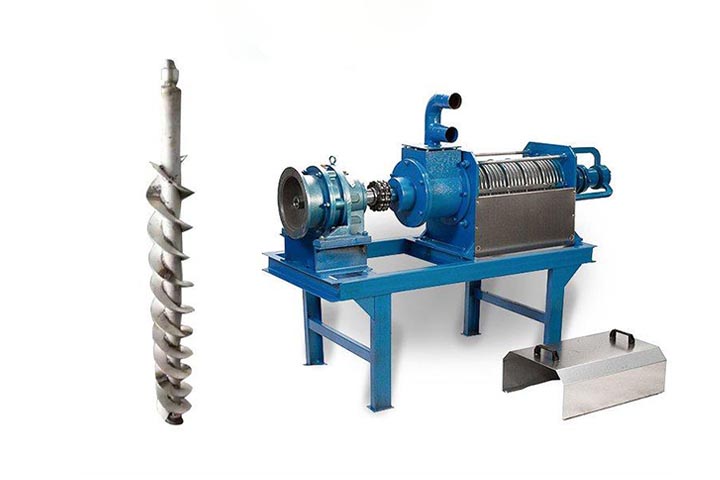

1) Feeding Device

Clay nickel mine water content is high, in the sticky bulk shape, the conveying process is difficult to measure and store, easy to cause the phenomenon of stacking and adhesion, resulting in movement speed of the red soil nickel ore in the dryer is slow, thus having the low output. Consideration should be given to reducing feed and using special dryer feeding devices.

2) Heating System

To reduce the red soil nickel ore moisture from the first 35% to 22%, it needs to overcome the low evaporation rate, so it is necessary to continue to supply high-temperature dry flue gas, resulting in high heat consumption. It has high requirements to hot blast furnace requirements are high, which is necessary to use efficient and energy-saving burner, to ensure the hot blast furnace constant heating temperature and the heat storage, and it needs to be equipped with a windshield wall, so that the operation of the furnace is positive pressure, but the entire drying system is micro-negative pressure control.

3)Dust Removal System

Exhaust gas emissions must be less than 100mg/m3 to meet the standard emissions after the processing by the dust removal system, so usually to choose the new type of wet dust collector, through which the dust ash discharge is not easy to leak, The reflux water of wet dust collector is directly used in the production of sintering primary mixing machine.

4) Heat Balance

Calorific value of blast furnace gas is low, pressure stability is low, and the system requires high heating temperature and stability and fast exhaust gas flow rate, need more than 800 ℃ of hot air supply, so that in the discharge process, to maintain the heat balance.

5) Stone Inclusion

Stones are contained in the clay nickel ore, so need to be screened before the feed. It needs to given fully consideration to the sturdiness of the feed plate and other components design, at the same time to consider the sealing effect of the import and export.

Dongding provides the most professional mud dryer solution and designs scientific selection for technical process of different materials.

Hot Products

Wood Chips Dryer

Sawdust Rotary Drum Dryer

Biomass Dryer

Biomass Pellet Production Line

Biomass Drying Machine

Bagasse Dryer