Lignite coal drying progress

Time : 2019-01-08 Writer : ddjx

High moisture content and low calorific value are the main features of lignite, in addition, low thermal efficiency of direct combustion, a large amount of greenhouse gas emissions, easy to weathering and spontaneous combustion, high transport costs, is not conducive to long-distance transmission and storage. Dongding has developed specialized drying lignite production line (Patent No. ZL 2013 2 0034342.6) can guarantee the quality of lignite after reducing the moisture content of lignite, enhancing brown coal calorific value, improving combustion efficiency, making more full use of coal resources . The system is a major breakthrough in the field of coal drying, greatly expanding the use of lignite.

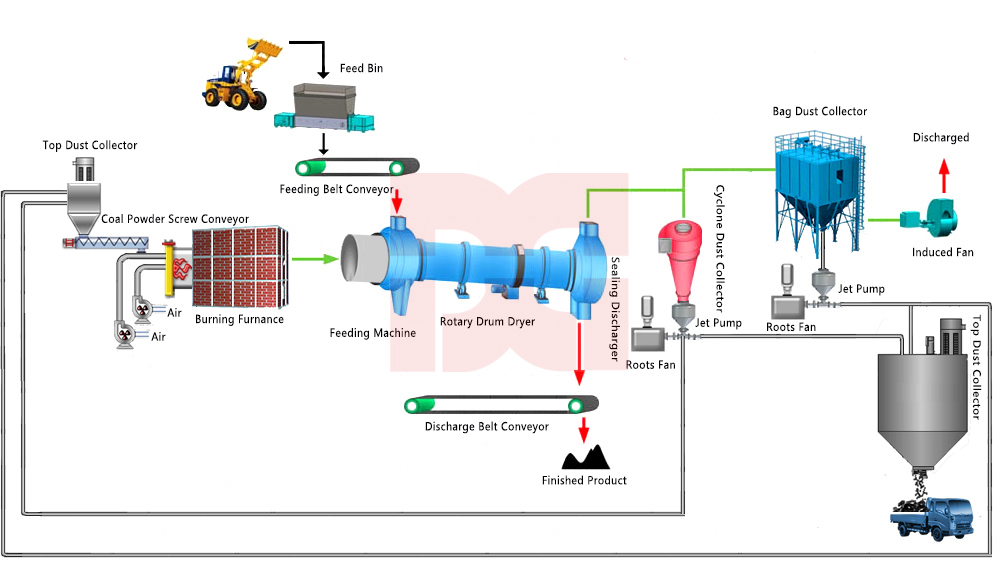

Systematical structure of Lignite coal drying system

Characteristics of lignite coal drying system

►System configuration is reasonable, meeting the lignite drying characteristics, equipped with special heat source spray furnace, which can use the dry lignite powder as fuel, reducing costs.

► After drying the lignite is not regurgitation, after drying the pulverized coal has a large physical and chemical changes, so that lignite can be converted from soft coal to hard coal, from hydrophilic to hydrophobic, to eliminate lignite regurgitation suction, realizing the long-distance transportation of lignite.

►High efficiency. Burnout rate of heat source used pulverized coal up to 99%, directly using the drying process received coal powder as a system heat source fuel, reducing fuel costs.

►High safety, the unique sealing structure of the discharge, and the realization of the entire non-oxidizing negative pressure operation, to eliminate the possibility of lignite combustion and explosion, safe and reliable.

►Low investment in equipment and low operating costs can recoup investment in a relatively short period of time.

Hot Products

Wood Chips Dryer

Sawdust Rotary Drum Dryer

Biomass Dryer

Biomass Pellet Production Line

Biomass Drying Machine

Bagasse Dryer