The Differences between vertical & horizontal pellet machine

Time : 2019-02-15 Writer : ddjx

The biggest difference of these two types of ring die pelleting mills is the working principle:

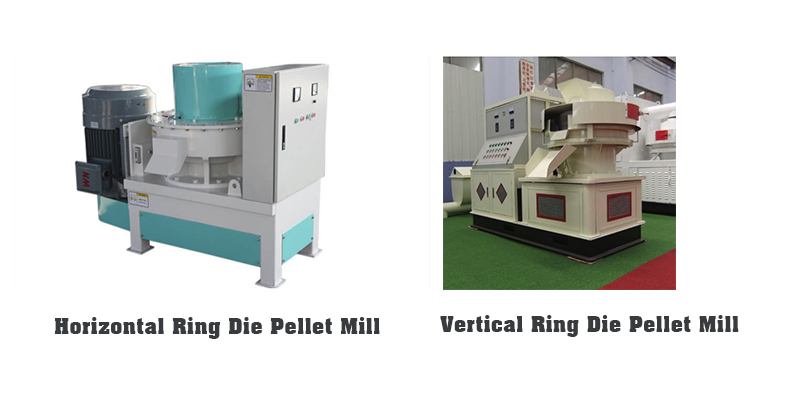

The vertical ring die pellet mill is specially designed to press the material which is hard to be bonded and shaped. The material can be loaded into the pelleting chamber in its own weight. Then, under the strong pressure between the rotating roller and the ring die, the material enters into the die holes to be formed into pellets. And this vertical ring die pellet mill is called light-weight material pellet mill as well. Because this vertical ring die pellet mill is more suitable for managing the materials with light weight, such as, rice hull, grass with light weight, straw, melon and fruit hull and the material which is not easy to form.

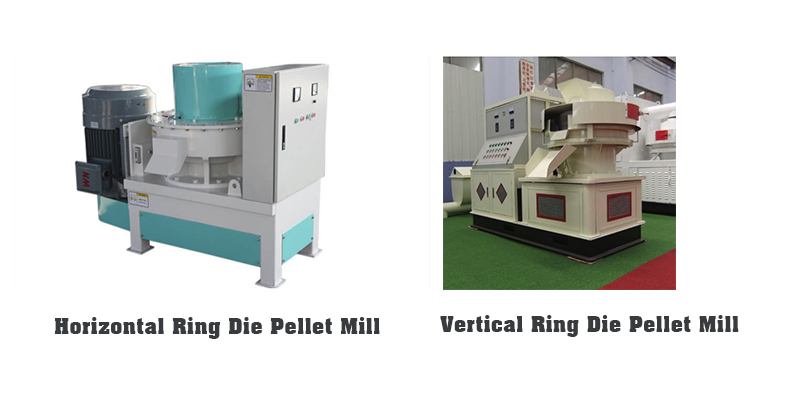

Differ from the vertical ring die pellet mill, the horizontal ring die pellet mill adopts the feeding auger to feed the material into the pelleting chamber through the stock bin. The material begin to be soft in the sealed pelleting chamber, and under the great extrusion between rotating ring die in a high speed and the roller, the soft material is pressed into the holes uniformly distributed on the die. After that, the formed cylindrical solid body out of the holes will be cut by the knife, thus discharged through the export hole.

As the different types of ring die pelleting mill, these two machines have their own unique advantages. Customers can choose one of them according to their own needs.

Vertical Ring Die Pellet Mill

1.Vertical ring die pellet mill is applicable for difficult molding materials with low adhesion rate, for example peanut shell, rice husk, fruit shell and sunflower husk; branches, bark, stem and other wood residues, various of crop stalks etc.

2.The new generation gearbox adopts high-precision gears, automatic lubricant pump system, keeping the gearbox working stability and warranty period.

3.In this vertical ring die pellet mill, the die holes with equidistant distribution are centered by the output shaft, making more powerful and stability of machine working.

4.Automatic lubrication system. The gear box is configured with circulation pump lubricating system controlled by the pinch roller to inject oil in timing. The oil pump motor can lubricate with automation and circulation making sure the shaft can be fully lubricated thus making the pellet machine running safely.

5.The blower system is equipped in side of the working bin, controlling the working time freely.

6.Feeding vertically with frequency conversion makes the feedstock uniform with no arch camber and easy heat dissipation.

Horizontal Ring Die Pellet Mill

1.The all-stainless steel feeder, configured with original imported frequency converter to control feeding uniformly and accurately.

2.Monitoring system is equipped, solving the problem of high temperature hazard in the pelleting chamber caused by the improper operation thus efficiently avoiding the danger of bursting and fire.

3.The components is made by international advanced manufacturing craft and designed according to the characteristics of the material from the customers, prolonging the service time of the equipment.

4.The ring die of feed machine with quick-release coupling reduces the time of replacing the ring die and improves the production efficiency.

5.Double-motor drive. The high strength SPB narrow V-belt drive transmit with stability and reliability but with low noise.

6.The horizontal ring die pelleting mill is configured with many kinds of ring dies with different aperture diameters and compression ratio, the customers can choose according to their needs.

Hot Products

Wood Chips Dryer

Sawdust Rotary Drum Dryer

Biomass Dryer

Biomass Pellet Production Line

Biomass Drying Machine

Bagasse Dryer