Biomass Pellet Production Line

Daily Capacity : 8-50t/d

Final Moisture : 8-10%

Material : wood chips, sawdust, bamboo shavings, wood shavings, wood shavings, straw, etc

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 8-50t/d

Final Moisture : 8-10%

Material : wood chips, sawdust, bamboo shavings, wood shavings, wood shavings, straw, etc

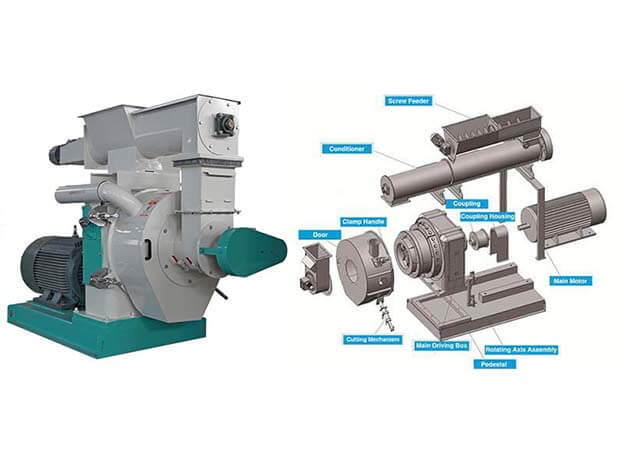

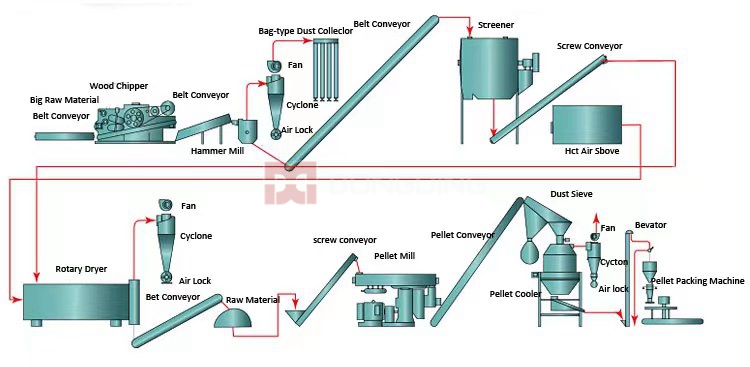

The biomass pellet production line including the process of crushing, drying, de-ashing and high-pressure molding, After being processed, the biomass pellet could approach the moisture of 8 to 10%, the combustion heat of 4000-4800 kilo calories per kilo gram, and ash content of 1% or less. The biomass production line can also process the alfalfa to make feed pellet.

We have biomass pellet production line with different capacity for example 500kg/h, 1t/h, 1.5t/h, 2t/h, 3t/h, 4-5t/h., etc. The final pellet can be 6mm,8mm, 10mm, 12mm, etc.The biomass pellet production line can used for wood chips, sawdust, bamboo shavings, wood shavings, wood shavings, barley straw, oat straw, wheat straw, rye, straw, rice straw, sorghum straw, stalk and corn straw, and potato vines, etc.

1. Crushing and broken system. If the raw material is the log, straw, leftover material and something bigger, needed to crush raw materials before pelleting.

2. Drying system. In general, the material with the moisture of 15-20% is suitable for granulating If more than 20%, needed to dry before granulating.

3. Granulating system. The final moisture of the pellet meets the safe store requirements of the pellet.

4. Cooling screening system. Biomass pellet after cooling screening machine go through belt conveyor into cooling sieve.

5. Packaging system. Send the biomass pellet into the packaging machine.

1. Compared with the single-drum dryer, the length of the machine is shortened by 50%, reducing the building area and saving about 40% project investment

2. Multiple Heating Source. Customers can choose the heating source according their situation, we can design the customized solutions

3. The system is optionally equipped with PLC control system and video monitoring system, which has a high degree of automation and simple operation

4. The system is equipped with control system, with a high degree of automation and simple operation

5. The system has a unique sealing structure, no thermal energy leakage

6. Low investment, low operating cost, and short investment recovery time

| Model | Capacity(t/h) | Motor power(kw) | Weight(ton) | Area(㎡) |

| DDKL1000 | 0.8-1.0 | 135 | 45 | 10x24 |

| DDKL1500 | 1.2-1.5 | 175 | 47 | 10x24 |

| DDKL2000 | 1.5-2.0 | 210 | 55 | 10x24 |

| DDKL3000 | 2.5-3.0 | 255 | 68 | 12x26 |

| DDKL5000 | 4.5-5.0 | 300 | 73 | 12x26 |

Wood Chips Dryer

Sawdust Rotary Drum Dryer

Biomass Dryer

Biomass Pellet Production Line

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com