Straw Dryer

Daily Capacity : 33-250t/d

Final Moisture : 12-15%

Material : corn straw, soybean straw, cotton straw, wheat straw, sorghum straw, etc.

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 33-250t/d

Final Moisture : 12-15%

Material : corn straw, soybean straw, cotton straw, wheat straw, sorghum straw, etc.

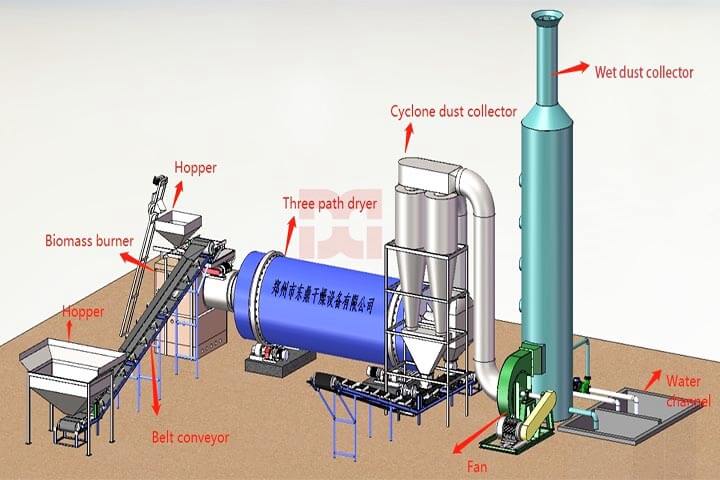

Straw dryer is widely used for drying corn straw, soybean straw, cotton straw, wheat straw, sorghum straw, forage, ginkgo leaf, mulberry leaf and other agricultural cellulose materials. For small capacity need, it can be met by the single path rotary drum dryer; for large capacity, the three (triple) pass rotary drum dryer is recommended. The large-scale straw dryer is with the advantage of high drying speed, automatic control, stable and reliable operation. Our company can also provide straw crushing and straw forming machine or straw pelleting system according to customers' needs in order to make a one-stop solution for our customers.

Firstly, straw (crushed if needed)is transported to the rotary drum dryer by the belt conveyor. Material moves to the end of dryer body, during which process wet material gets fully contact with the hot air. After drying, most of the dry material is discharged through the belt conveyor. The left material mixed with dust goes into the cyclone dust collector and the bag dust collector in sequence, where the dust will be collected. Lastly, with the function of induced draft fan, the left material will discharged through the conveyor.

1. Designed inner structure for straw. High drying efficiency to 90-95%;

2. The system is equipped with PLC system and video monitoring system, with a high degree of automation and simple operation;

3. The system has a unique sealing structure, no thermal energy leakage;

4. Automatically remove impurities and iron to ensure that impurities do not enter the following drying process;

5.Multiple Heating Sources. Customers can choose the heating source according their situation, we can make the customized solutions.

Straw Drying and Pelleting Site

Straw Dryer Cases

| Device Specification | DDJG1210 | DDJG1410 | DDJG1610 | DDJG2010/3 | DDJG2210/3 | DDJG2510/3 | DDJG2512/3 | DDJG2912/3 |

| Daily Processing Capacity(t/d) | 33.6 | 40.8 | 58.9 | 131.4 | 145.0 | 167.7 | 204.0 | 247.0 |

| Daily Output(t/d) | 15.6 | 19.2 | 27.7 | 61.8 | 68.2 | 78.9 | 96.0 | 116.2 |

| Water Evaporation Capacity (t/h) | 0.75 | 0.90 | 1.30 | 2.90 | 3.20 | 3.70 | 4.50 | 5.45 |

| Raw Material Water Content(%) | 60±5 | |||||||

| Dried Material Water Content(%) | 12-15(adjustable) | |||||||

| Drying Temperature (℃) | 350-550 | |||||||

| Total Weight(kg) | 32 | 40 | 55 | 95 | 100 | 125 | 145 | 165 |

| Plant Area(㎡) | 15000 | 17000 | 21500 | 26500 | 28500 | 370000 | 41000 | 45500 |

| Device Specification | 5m*14m | 5m*14m | 6m*16m | 8m*16m | 8m*16m | 10m*16m | 10m*18m | 10m*20m |

we can also make customized models according to your needs

Wood Chips Dryer

Sawdust Rotary Drum Dryer

Biomass Dryer

Biomass Pellet Production Line

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com