Screw Press Dehydrator

Daily Capacity : 40-100t/d

Final Moisture : 75%-60%

Material : Brewery spent grains, pomace, vegetable leaves, food waste, etc

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 40-100t/d

Final Moisture : 75%-60%

Material : Brewery spent grains, pomace, vegetable leaves, food waste, etc

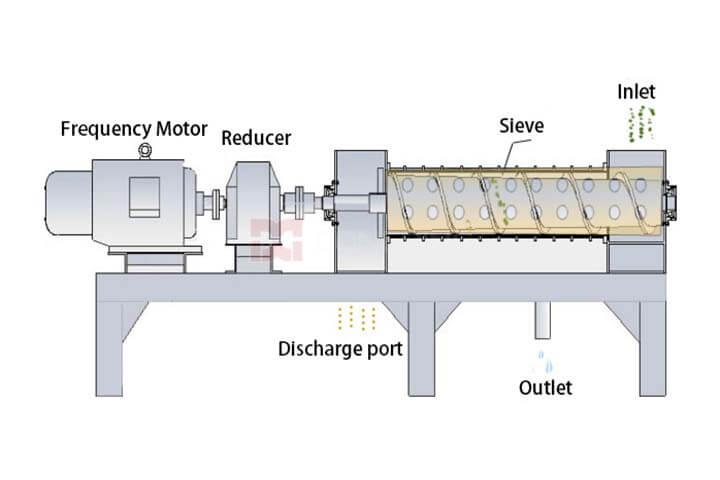

The screw press dehydrator is composed of a feed box, a screw sieve, a water filter frame, a filter base, a motor, and a reducer, etc. It features with high strength, high pressure bearing, no deformation, no clogging, corrosion resistance, wear resistance, no slipping, easy maintenance, and long service life, etc.

The screw press dehydrator is widely used in the dehydration of dregs with high water content , such as distiller's spent grains, fruit residue ( pomace ), alfalfa grass, coffee grounds, cassava residue, etc. It can be used before drying process, reducing the burden of dryers and reduce the drying cost. It’s an essential processing equipment before drying raw mataril with high moisture.

The raw material with high water content is fed evenly from the feed box and moves along the axis to the discharge port under the push of the spiral rotating blade. Under the huge extrusion force generated by interactions between changing screw pitch, screw and the adjusting baffle, the material is dehydrated fully. The water is discharged through the screen at the water outlet, and the dehydrated material is discharged at the discharge port.

a. The screw press dehydrator has its own propeller inside the spiral, which integrates crushing and pressing, saving space and cost;

b. The screw adopts a feeding plate with a special structure, and is equipped with a screw blade device to ensure the raw material transported evenly and pressed uniformly;

c. Adopting superimposed compression, efficient extrusion can be achieved with low power, energy saving;

d. Stainless steel filter is used, which features with wear-resistant, corrosion-resistant, durable and has good filtration performance;

e. The sieves vary from different raw material, customized solution.

| Models | DDTH250 | DDTH300 | DDTH350 | DDTH400 | DDTH450 | DDTH500 |

| Power (kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 |

| Speed Range (r/min) | 125 -- 1250 | |||||

| Weight (t) | 0.75 | 1.1 | 1.5 | 2.0 | 3.5 | 5.0 |

| Capacity (t/d) | 40 | 70 | 90 | 120 | 160 | 200 |

| Floor Space (㎡) | 2.1 | 2.1 | 2.1 | 5.04 | 5.04 | 5.04 |

Screw Press Dehydrator

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com