Beer Dregs Dryer

Daily Capacity : 63-256t/d

Final Moisture : ≤12%

Material : beer dregs, brewery vinasse in brewery, distiller grains in winery, cane bagasse, soybean residue, etc.

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 63-256t/d

Final Moisture : ≤12%

Material : beer dregs, brewery vinasse in brewery, distiller grains in winery, cane bagasse, soybean residue, etc.

Beer dregs dryer can quickly pre-dehydrate the wet beer slag with a moisture content of about 85% and then dry it to a dry product with a moisture content of about 10%.

The lees can be developed into non-conventional feed, which can greatly ease the feed resources. Stressful conditions reduce the cost of farming and increase economic efficiency.

At present, this set of equipment has been put into use by many domestic beer companies and feed processing companies.

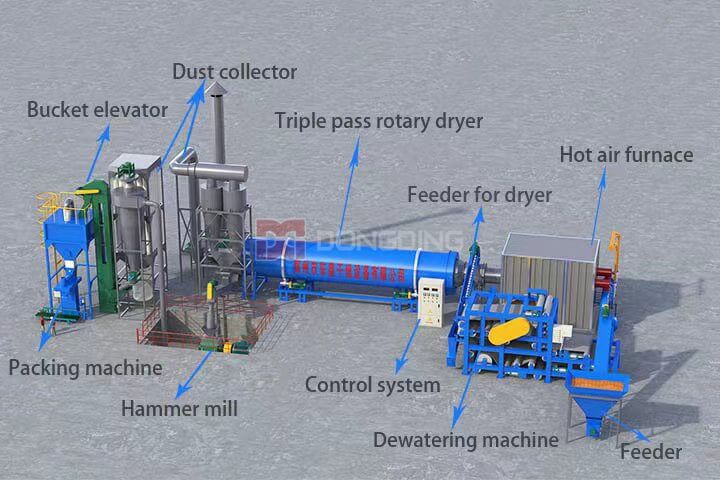

The dryer plant consists of dehydration machine, heat source, feeder, drum drying system (single cylinder or triple cylinder), discharge machine, induced draft fan, unloader and power distribution Cabinet, smashing system, packing system and other components.

The specific process is as follows: wet slag with moisture content above 80% is squeezed and dehydrated by the dehydration equipment and the moisture is reduced to about 65%, and then through the spiral feeding machine enters the drying system to be dried. Uniformly distributed in the roller board, under the action of rolling, materials are fully dispersed and contacted with the hot air, speeding up the drying heat transfer, mass transfer. During the drying process, the beer slag is discharged to the stencil unloader valve of the Beer dregs dryer under the action of the inclined board and the heat medium. The dried beer slag processed by the system has good color, aromatic odor and strong animal palatability.

1. It has high mechanization degree, high production capacity and continuous operation.

2. The structure of dryer is excellent, simple, easy operation.

3. Low failure rate, low maintenance cost and low power consumption.

4. Good uniformity , rare delicacy after drying.

5. Use frequency conversion to control material flow, which can be easily adjusted according to the needs of users.

| Device Specification | DDJG1210 | DDJG1410 | DDJG1610 | DDJG2010/3 | DDJG2210/3 | DDJG2510/3 | DDJG2512/3 | DDJG2912/3 |

| Daily Processing Capacity(t/d) | 33.6 | 40.8 | 58.9 | 131.4 | 145.0 | 167.7 | 204.0 | 247.0 |

| Daily Output(t/d) | 15.6 | 19.2 | 27.7 | 61.8 | 68.2 | 78.9 | 96.0 | 116.2 |

| Water Evaporation Capacity (t/h) | 0.75 | 0.90 | 1.30 | 2.90 | 3.20 | 3.70 | 4.50 | 5.45 |

| Raw Material Water Content(%) | 60-80 | |||||||

| Dried Material Water Content(%) | 12-15(adjustable) | |||||||

| Drying Temperature(℃) | 350-550 | |||||||

| Total Weight(kg) | 32 | 40 | 55 | 95 | 100 | 125 | 145 | 165 |

| Plant Area(㎡) | 15000 | 17000 | 21500 | 26500 | 28500 | 370000 | 41000 | 45500 |

| Device Specification(m) | 5*14 | 5*14 | 6*16 | 8*16 | 8*16 | 10*16 | 10*18 | 10*20 |

we can also provide customized models according to your needs

Brewery Spent Grain Dryer

Alfalfa Rotary Dryer

Yeast Dryer

Pomace Dryer

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com