Cassava Residue Dryer

Daily Capacity : 63.5-268.0t/d

Final Moisture : 12-15%(adjustable)

Material : cassava pulp, potato dregs, etc

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 63.5-268.0t/d

Final Moisture : 12-15%(adjustable)

Material : cassava pulp, potato dregs, etc

Cassava residue can be used as livestock feed after drying. The cassava residue dryer produced by our company can dehydrate all kinds of cassava dregs with moisture of about 80%, into the final products with moisture less than 12%.

The cassava residue dryer is equipped with special dehydration, temperature regulating, lifting, guiding, and dispersing devices, which effectively avoid wall sticking and blocking.

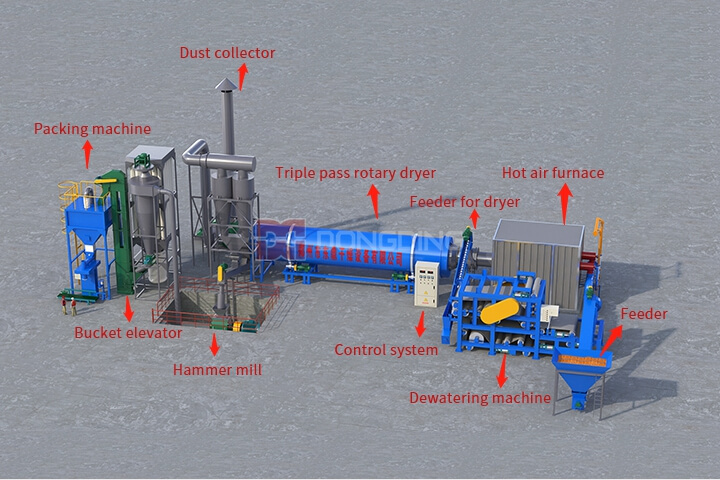

we can provide the full dryer plant, which includes heating part, feeding machine, crushing machine, rotary dryer, discharging machine and cyclone dust collector,etc, and this cassava residue dryer plant is suitable for drying cassava and potato residue; cassava pulp and bean dregs, etc.

1. After broken up and crushed in the channel, the material is loose and the viscosity is greatly reduced, which solves the wall sticking phenomenon in the drying process;

2.The system adopts special heat source and heat preservation system to reduces the energy consumption effectively;

3.The system has a unique sealing structure, and is equipped with perfect dust removal device, to prevent dust overflow;

4.The operating parameters can be changed according to different material properties (moisture content, ash content, particle size composition), so that the material can form a stable full-break fabric curtain in the dryer cylinder, and the mass heat exchange is more sufficient;

5.The entire drying system adopts centralized electrical control, with high automation and easy operation;

6.After been dried; it can be connected with crushing, mixing, granulating, packaging and other follow-up sections to produce potato residue pellet feed products.

| Device Specification | DDJG1210 | DDJG1410 | DDJG1610 | DDJG2010/3 | DDJG2210/3 | DDJG2510/3 | DDJG2512/3 | DDJG2912/3 |

| Daily Processing Capacity(t/d) | 33.6 | 40.8 | 58.9 | 131.4 | 145.0 | 167.7 | 204.0 | 247.0 |

| Daily Output(t/d) | 15.6 | 19.2 | 27.7 | 61.8 | 68.2 | 78.9 | 96.0 | 116.2 |

| Water Evaporation Capacity (t/h) | 0.75 | 0.90 | 1.30 | 2.90 | 3.20 | 3.70 | 4.50 | 5.45 |

| Raw Material Water Content(%) | 60-80 | |||||||

| Dried Material Water Content(%) | 12-15(adjustable) | |||||||

| Drying Temperature(℃) | 350-550 | |||||||

| Total Weight(kg) | 32 | 40 | 55 | 95 | 100 | 125 | 145 | 165 |

| Plant Area(㎡) | 15000 | 17000 | 21500 | 26500 | 28500 | 370000 | 41000 | 45500 |

| Device Specification(m) | 5*14 | 5*14 | 6*16 | 8*16 | 8*16 | 10*16 | 10*18 | 10*20 |

we can also provide customized models according to your needs

Brewery Spent Grain Dryer

Alfalfa Rotary Dryer

Yeast Dryer

Pomace Dryer

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com