Biomass Pellet Burner

Daily Capacity : 44-300kg/h

Final Moisture :

Material : wood chips, sawdust, biomass pellet

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 44-300kg/h

Final Moisture :

Material : wood chips, sawdust, biomass pellet

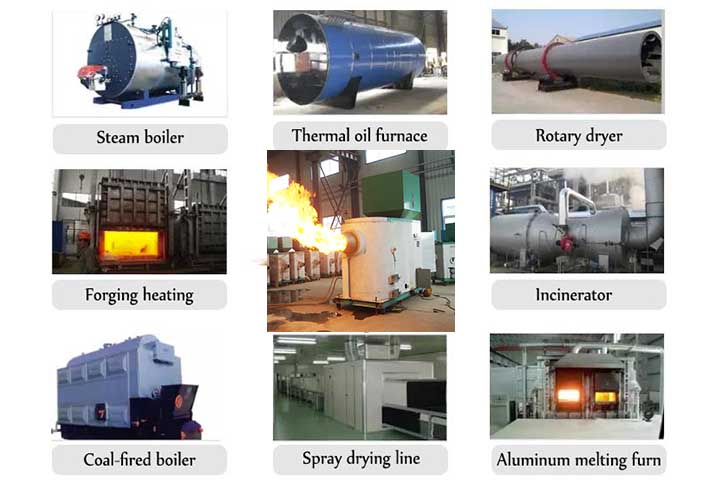

Biomass burner uses biomass particles or biomass pellet as fuel, with high efficiency and energy saving, clean and environmental protection, full automatic control, easy to install and use, a wide range of applications and many other advantages in one, using unique boiling semi-gasification, complete low-nitrogen combustion, ithe efficiency of which can reach more than 98%, widely used in various types of boilers, industrial kilns and spraying, drying, transfer, melting aluminum and other production lines and other thermal energy industries.

Application of biomass burner

a. Chemical and pharmaceutical: Manufacture & dry

b. Painting industry: bake coating & solidified spray

c. Textile, printing, dyeing, non woven enterprises: heat setting, thermosol dyeing, bake, hot air stenter

d. Foundry industry: dry welding rod & solder

e. Abrasives industry: dry grinding wheel & thermal insulation material, fiberglass, aluminosilicate fiber & FBT etc

f. Agriculture products and food industry: bake & dry coffee, tobacco,vegetable, grain, noodles, seafood, bean, etc

g. Heating engineering: heating for factory, civil building, etc

1.Complete combustion and high combustion efficiency

The equipment operates under the condition of low pressure, which effectively avoids the phenomenon of tempering and degasification.

The Gasification chamber burns at low temperature and pyrolysis at high temperature.

2.Wide thermal load adjustment range

The thermal load of the burner can be adjusted quickly in the 30%-120% range of the rated load, starting fast and responsive.

3.Clean and environmental protection

Low nitrogen: NOx≤300mg/Nm3;

Low dust, no sulfur: dust is 1/10-1/20 of Ⅱ type of bituminous coal, sulfur is 1/100 of Ⅱ type of bituminous coal; CO2 Zero Emissions:

4.Low investment and low operating costs

Biomass combustion mechanism design is reasonable, can be used for a variety of equipment transformation, whose cost is only 29% of fuel boilers, 60% of gas boilers, 20% of electric heating boilers.

Model | sawdust | coal | diesel oil | heavy oil | fuel gas | heating value | size of |

consumption(kg/h) | consumption(kg/h) | consumption(kg/h) | consumption(kg/h) | consumption(kg/h) | (Kcal/h) | burner(mm) | |

DD-LK0.35 | 44 | 40 | 20 | 21 | 24 | 200000 | 1700×750×1400 |

DD-LK0.5 | 70 | 65 | 30 | 31 | 38 | 300000 | 1800×900×1500 |

DD-LK1.0 | 155 | 140 | 60 | 63 | 75 | 600000 | 2400×2200×1550 |

DD-LK1.5 | 230 | 210 | 90 | 94 | 113 | 900000 | 2400×2400×1800 |

DD-LK2.0 | 310 | 280 | 120 | 125 | 150 | 1200000 | 2400×2400×2000 |

DD-LK3.0 | 460 | 415 | 180 | 188 | 225 | 1800000 | 2600×2500×2200 |

DD-LK4.0 | 600 | 540 | 240 | 250 | 300 | 2400000 | 2600×2600×2350 |

Biomass Pellet Burner

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com