Animal Manure Dryer

Daily Capacity : 20-320T/D

Final Moisture : 12%-15%

Material : cow dung, chicken manure, pig manure, etc.

- Get Price

-

Welcome to visit the factory at anytime!

Daily Capacity : 20-320T/D

Final Moisture : 12%-15%

Material : cow dung, chicken manure, pig manure, etc.

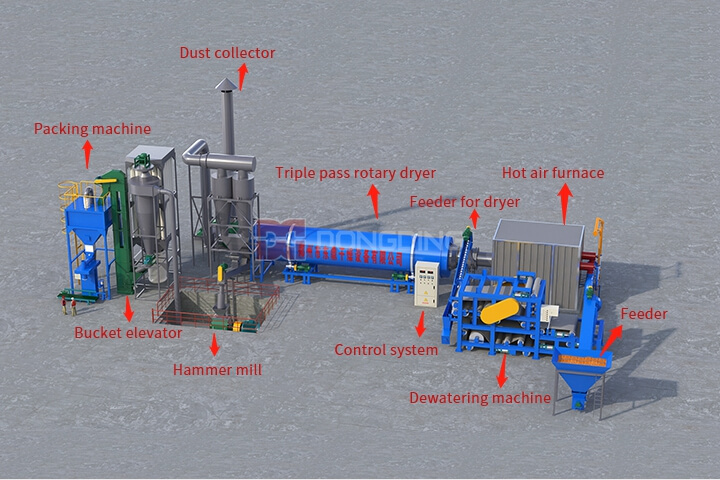

The animal manure rotary dryer is a high-efficiency, continuous drying equipment designed specifically for processing high-moisture, high-viscosity organic waste, such as livestock manure (cow dung, chicken manure, pig manure). This equipment rapidly reduces the moisture content of manure (usually from 60%-80% to 10%-30%) through multi-stage contact between high-temperature hot air and the material, and finally produces dry, odorless organic fertilizer raw materials or feed that are easy to store or further process. Its closed operating mode effectively reduces environmental pollution while achieving the resource utilization of waste, making it widely used in farms, organic fertilizer plants, and environmental protection projects.

Organic Fertilizer Dryer

Animal Manure Dryer

Cow Dung Dewatering Machine

Our factory is located in Zhengzhou City, Henan Province, and there are 5000 square meters of standardized industrial workshop. The number of staffs is more than 500, together we are dedicated to the R & D and production, installation, after-sales service and technical consultation of the drying equipment.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

We have strict quality control system and full set of service. Our products have been exported to over 120 countries such as Indonesia, the Philippines, Vietnam, Thailand, India, Kenya, Nigeria, Romania and many other countries and regions, totally 600+ drying cases all over the world. We are here to provide better products and service for you.

Consult to Get Price

NEED A SOLUTION? USE THE FORM TO GET IN TOUCH!

Email : dongding@zzddjt.com

Email : dongding@zzddjt.com